Top CBD Oils Online

Multi-Brand Top CBD Products Online

Top CBD Oils:

1. Tree of Life Hemp Oil Extract

A 9000mg CBD Oil Extract, that helps with:

- Inflamation. Helps eliminate or reduce inflammatory issues in the body.

- Eases Discomfort. Minimizes discomfort do you can sleep better at night

- Boosts Mood. Improves overall mood and energy and reduces anxiety.

2. CBD Care Oil

CBD Care Oil is a Isolate CBD that:

- Reduces Chronic Pain & Aches

- Relieves Anxiety & Stress

- Enhances Your Mood

- Promotes Better Sleep

- 100% Pure CBD

CBD Care Oil ill tune your entire endocannabinoid system (the network of receptors found throughout your body, including your brain, organs, glands).

3. CBD Pure Relief

CBD Pure Relief is a full-spectrum CBD oil, made especially for relief.

Experience relief from occasional aches and pains with CBD Pure Relief a developed formula that harnesses the power of CBD, THC and Terpenes.

CBD Pure Relief is third-party tested to ensure the product’s purity.

4. CBD Pure Sleep

CBD Pure Sleep is a high-quality, full-spectrum CBD oil, specially formulated to support better sleep patterns. Designed with your rest in mind, this blend combines the soothing effects of CBD with additional cannabinoids CBN and THC.

CBD Pure Sleep is third-party tested to ensure the product’s purity.

5. CBD Pure Calm

CBD Pure Calm is a high-quality, full-spectrum CBD oil, specifically crafted to foster a sense of relaxation and tranquility. Designed with your mental wellbeing in mind, this blend combines the soothing effects of CBD with additional cannabinoids CBG and THC.

CBD Pure Calmis third-party tested to ensure the product’s purity.

6. CBD Pure Hemp Oil

CBD Pure Hemp Oil – Contains all-natural Cannabidiol (CBD), Terpenes, and other Cannabinoids.

All products are quality tested by an independent third-party lab to ensure you get the best product possible, and the potency results are made public for your review.

Top CBD Edibles

1. Greenhouse Research Pure CBD Gummies

Greenhouse Research Pure CBD Gummies – Delicious Gummies, Fast Acting and Effective CBD

- Reduces Chronic Aches and Pain

- Alleviates Anxiety and Depression

- Enriches Mood and Mindset

- Amplifies Focus and Mental Clarity

- 100% All Natural and Pure CBD Oil

2. Bliss Bitz CBD Gummies

Bliss Bitz CBD Gummies, Broad-spectrum CBD extracts that contain the whole family of phytocannabinoids. Bliss Bitz CBD Gummies, undergo extensive certified third-party testing to ensure absolute purity and consistent quality. Bliss Bitz CBD Gummies tests every batch to verify CBD content, THC-free, and zero contaminants.

3. ProLife Labs CBD Gummies

ProLife Labs CBD Gummies, full spectrum CBD:

- Reduces Pain & Chronic Aches

- Advanced C02 Extraction Technology

- Relieves Anxiety & Stress

- Superior Sublingual Delivery System

- Promotes Healthy Sleep

- Enhances Focus & Clarity

- Made in the USA

4. Harmony Leaf CBD Gummies

Harmony Leaf CBD Gummies is a Isolate CBD, from Hemp Extract, that:

- Reduces Chronic Pain & Aches

- Relieves Anxiety & Stress

- Enhances Focus & Clarity

- Promotes Healthy Sleep

Harmony Leaf CBD Gummies being an Isolate CBD is Pure CBD that does Not show on drug tests.

5. CBD Care Gummies

The cannabinoids found in CBD Care Gummies are the same compounds that regulate mood and pain in the brain and body.

CBD Care Gummies is also widely available to be used as a supplement for anxiety, insomnia, and used as an option for chronic pain.

Top CBD Patches

1. Grown Science Nano Hemp Patch

Benefits of Grown Science Nano Hemp Patch:

- It is made of industrial hemp sourced from premium, organic, non-GMO farms.

- Every batch is tested for quality, potentcy, and to ensure it’s free of pesticides, solvents, and heavy metals.

- Grown Science Nano Hemp Patch, manufactured in the USA from USA-sourced ingredients.

Top CBD Topicals

1. CBDPure Muscle & Joint Formula

CBDPure Muscle and Joint Formula is a unique blend of plant-based compounds and phytonutrients that help soothe and rejuvenate strained muscles and joints. Its heavy-hitting ingredients include full-spectrum CBD, Willow Bark and menthol to amplify the fast-acting therapeutic effects.

Top CBD Pets

CBD Pet Hemp Oil

CBD Pet Hemp Oil contains a rich combination of cannabinoids, flavonoids and terpenes – producing a far superior health benefit than CBD alone.

Every bottle of CBD Pet Hemp Oil has been tested by an independent third party lab to make sure your pet gets the full benefits of ultra-pure CBD oil.

Top CBD Oils Online Blog Posts:

CBD for Pet Anxiety: Do you have a pet who experiences anxiety? If so, you’re not alone. Many pet owners struggle with finding a solution to help their furry friend feel calm and relaxed. Fortunately, CBD may be able to help. In this article, we’ll explore benefits of CBD for pet anxiety and provide tips […]

CBD for Pets Near Me: As a pet owner, you always want to ensure your furry friend is in the best of health. One emerging trend in the world of pet wellness is the use of CBD, which is derived from the hemp plant. But where can you find CBD for pets near you? Let’s […]

Wondering whether to buy CBD online or in-store? It’s a question that many people are asking these days. With the rise of CBD’s popularity, there are now more options than ever for buying this natural supplement. But with so many choices, it can be difficult to know which one to choose. At Top CBD Oils […]

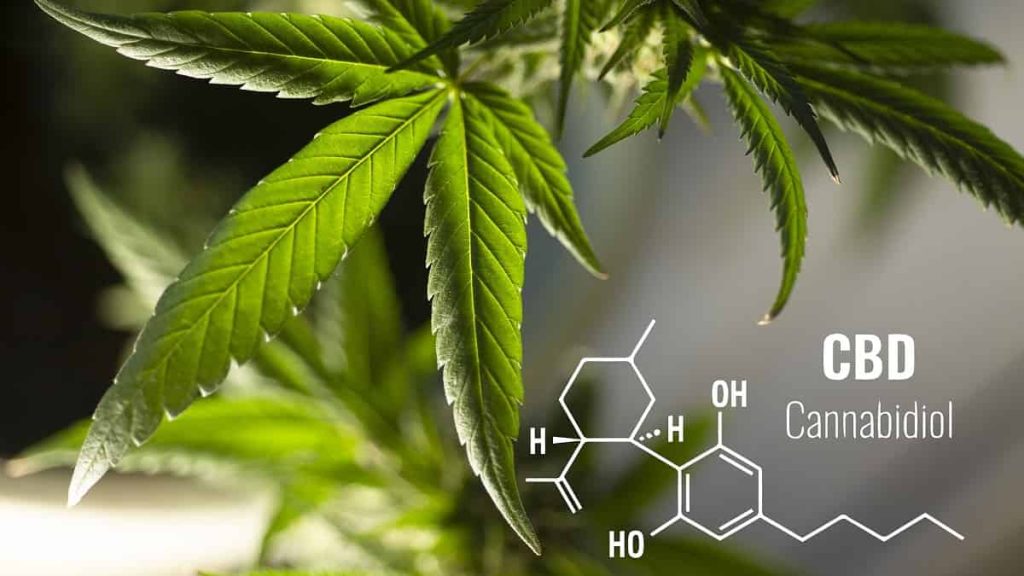

Welcome to our comprehensive guide to shopping for CBD oil online and relieving your pain today. In this article, we will provide you with all the information you need to know about CBD oil online, its health benefits, and how to buy it online. CBD oil, short for Cannabidiol oil, is a non-psychoactive compound found […]

Order CBD Oil Online: Are you feeling anxious or stressed? Anxiety disorders are among the most common mental health conditions that affect millions of people worldwide. While there are various treatments available, many people are turning to CBD oil to reduce their anxiety symptoms. CBD oil is a natural product that has gained immense popularity […]

How to determine the right CBD Oil dosage: Determining the right CBD oil dosage can be a daunting task for many individuals. With the increasing popularity of CBD products, it’s essential to understand how to use them safely and effectively. CBD oil has many potential benefits, including reducing anxiety, managing pain, and improving sleep. However, […]

How CBD oil works: CBD oil has become a popular natural remedy for various ailments in recent years. People are turning towards this alternative medicine due to its various health benefits, including relieving pain, reducing anxiety and depression, alleviating cancer-related symptoms, and improving heart health. However, before using CBD oil, it’s crucial to understand how […]

CBD Online Reviews: As the CBD industry continues to grow, it can be overwhelming to navigate the plethora of CBD products available online. With so many different brands and types of products, it can be difficult to know which ones are right for you. That’s where online reviews come in. Reading reviews from other consumers […]

Before buying CBD products online, it’s important to read reviews. That’s because there are so many different CBD products available online, and it can be tough to figure out which ones are high-quality and which ones are not. In this article, we’ll take a look at why reading reviews is so important when buying CBD […]

Full Spectrum CBD Oil: Are you curious about CBD oil? Have you heard about full-spectrum CBD oil, but aren’t sure what it is or how it differs from other types of CBD products? If so, you’ve come to the right place. At Top CBD Oils Online, we’re committed to providing high-quality, full-spectrum CBD oil to […]